3D Printing

My experience with 3D printing

Posted: August 22, 2020

I have used and owned several 3D printers, with these machines I have printed prototypes for school projects, parts for my hexapod robot and more.

Most of my machines have been Fused Deposition Modeling (FDM) based, which is a 3D printing process that uses a continuous spool of filament. The filament I typically use is made from a plastic called Polylactic Acid – more commonly known as PLA. The filament is fed from a spool through the extruder head, and is deposited on the growing model. The print head is moved under computer control to define the printed shape.

Creality CR-20

The first machine I ever bought was the Creality CR-20, it is similar to the popular Ender 3 printer from Creality. It was a great printer out of the box (especially for the price). But after some months of using it, I already wanted to improve the print quality with some upgrades such as a direct drive extruder and magnetic flex-plate for the build-plate.

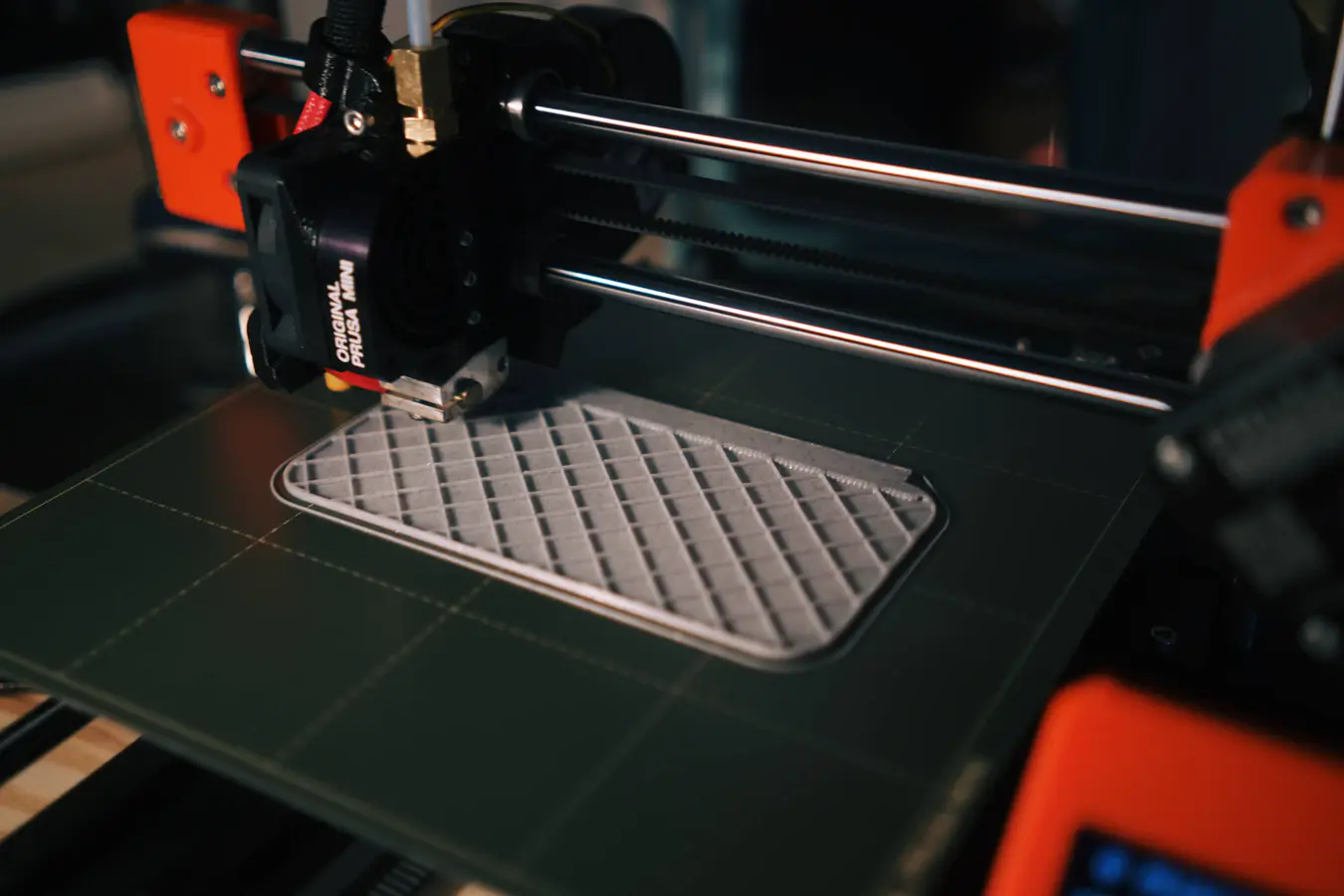

Prusa Mini

I had a lot of fun with my Creality CR-20 printer, but the overall size of the printer was just too large for me. So I decided to replace it with an Original Prusa Mini from Prusa Research, a well known manufacturer of 3D printers from the Czech Republic.

The Prusa Mini with it’s 32-bit processor comes with a ethernet port to connect it to a local network. It currently only shows a simple dashboard with some live printing information, but Prusa Research is also working on an API that will allow us to build our own dashboards and print farms – which I will definitely try in the future!

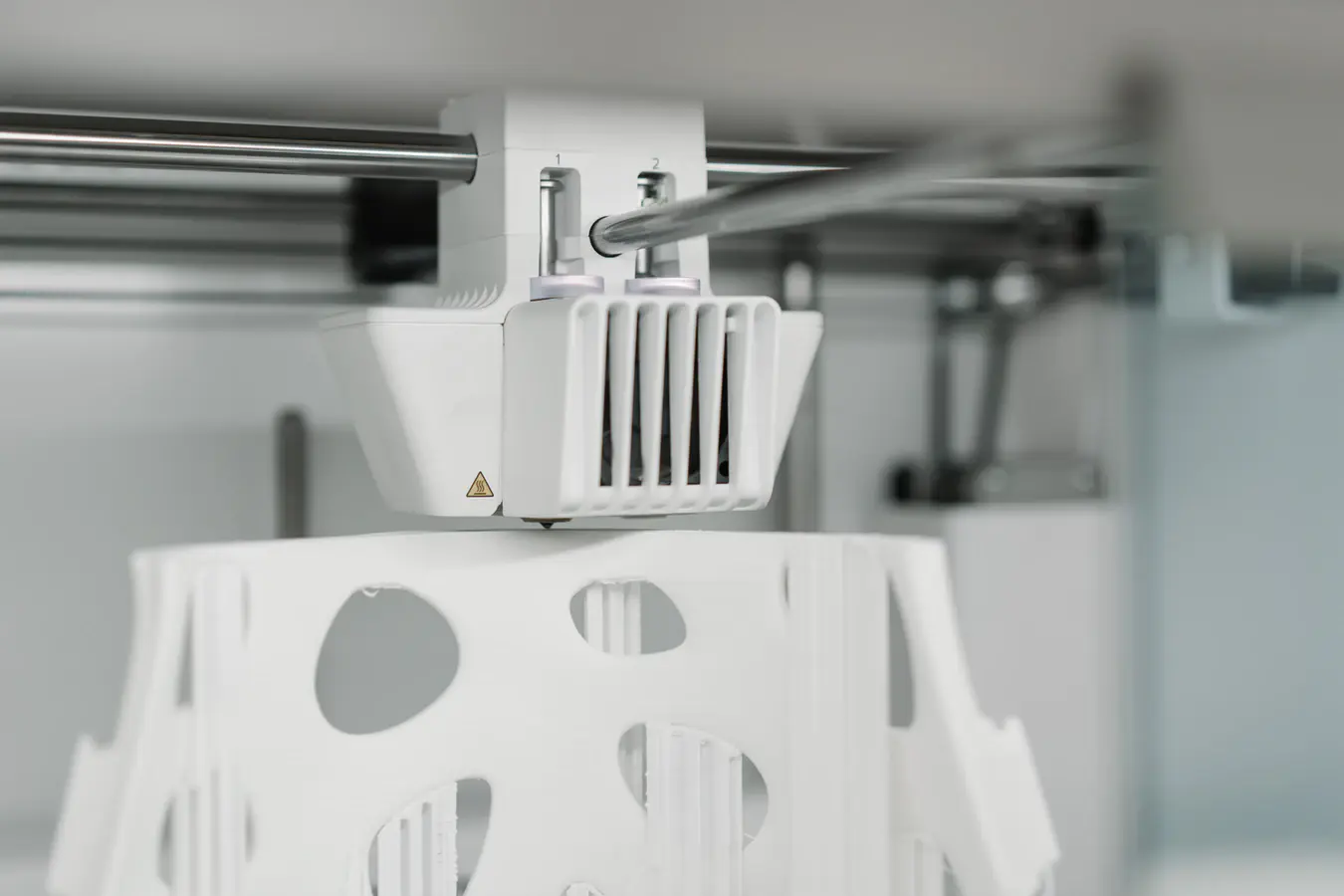

Ultimaker 3 and S5

I have also had the opportunity to use multiple different Ultimaker printers, these printers are made here in the Netherlands and are aimed at professionals and businesses.

As an assignment for the Dutch Navy I wrote a log script for an Ultimaker S5, which would track certain sensors during printing. This data could prove that the part has been printed correctly without any abnormalities, allowing better part certification after printing.